Criteria for the right Industrial mixing equipment

The experience of our engineering office to design your industrial mixing equipment

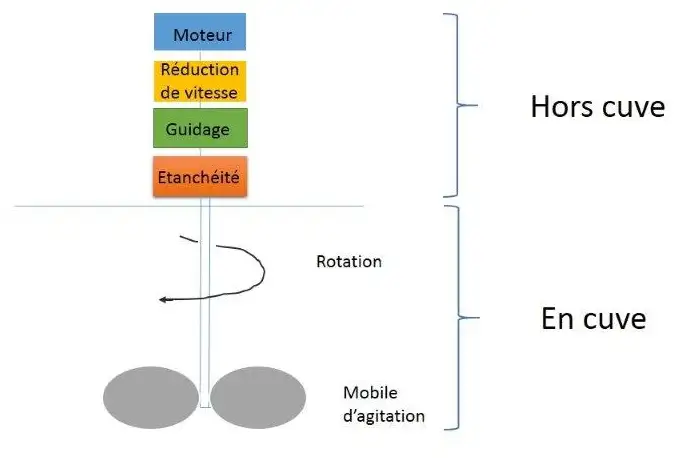

The experience of our engineering office and our calculation tools mean we can hydraulically and mechanically size the machines we produce. Each industrial mixing equipment /is designed and built according to three criteria: the nature of the elements to be mixed, the agitation objective, and the environment.

The elements to be mixed

- Liquid / miscible liquid

- Liquid / non-miscible liquid

- Liquid /solid

- Liquid / gas

- Circulating liquid

- Solid /solid

The agitation objective

This essential data enables us to adapt our solution to your requirements.

- Liquid / liquid mixture : mashing, concentration, dilution, heat exchange, emulsion, extraction, evaporation, flocculation, fluidisation, homogenisation, washing, liquefaction, temperature maintenance, maintain homogeneous, churning, blending, pumping, preparation of reagent, chemical reaction, storage.

- Liquid / solid mixture : attack, attrition, catalysis, crystallisation, deflocculating, stirring, disintegration, digestion, dispersion, dissolution, flocculation, melting or remelting, incorporation, lixiviation, maintain in suspension, maintain homogeneous, suspension, methanisation, precipitation, preparation of reagent, pH, storage.

- Liquid / gas mixture: absorption, degassing, foam suppression, dispersion, reaction.

- Solid / solid mixture: mixing, homogenisation, dispersion.

Conditions and environments

The operating conditions and method, the type of fluids, the ATEX zone around and in the tank are data that we take into account when designing the mixer.

- Pressure: from absolute vacuum to 50 bars, it needs to be measured to define the type of sealing and the calculation of the seat flange.

- Temperature: with variations that can range from -30°C to +300°C for some mixes, we need to check whether sealing and/or cooling at the agitation head need to be put in place.

- Types of fluids: Newtonian, non-Newtonian or sticky, these data have an impact on how the mixer and its power are calculated.

- Atmosphere: for mixers operating in explosive environments (ATEX), zoning, the temperature class and types of protection inside and outside the reactor need to be considered.