Designing a new industrial mixing machine

We can design your new custom industrial mixing machine, from the simplest to the most complex

To provide the right mixer for our customers’ specific needs, mutual cooperation and dialogue are essential.

We work on all types of project:

- Specifications drawn up with our support

- Specifications drawn up by the customer

- Cloning of existing machines.

Wherever possible, we base our quotes on similar projects that we adapt to the new requirements. By limiting customisation, we can capitalise on our successes and produce machines that are competitively priced.

Simple and complex mixers

When an industrial mixing machine is simple, due to the products used and the mixing objective, the mechanical and hydraulic design remains quite traditional.

The most sophisticated industrial mixers are complex in:

- their hydraulic requirements: when for example there is no traditional solution for a new product that is very difficult to mix;

- or in their construction: for example when special machining is required or when the material in contact with the process fluid is very difficult to weld;

- or in the constraints of the specifications, requiring us to think outside the box.

Engineering and calculation resources

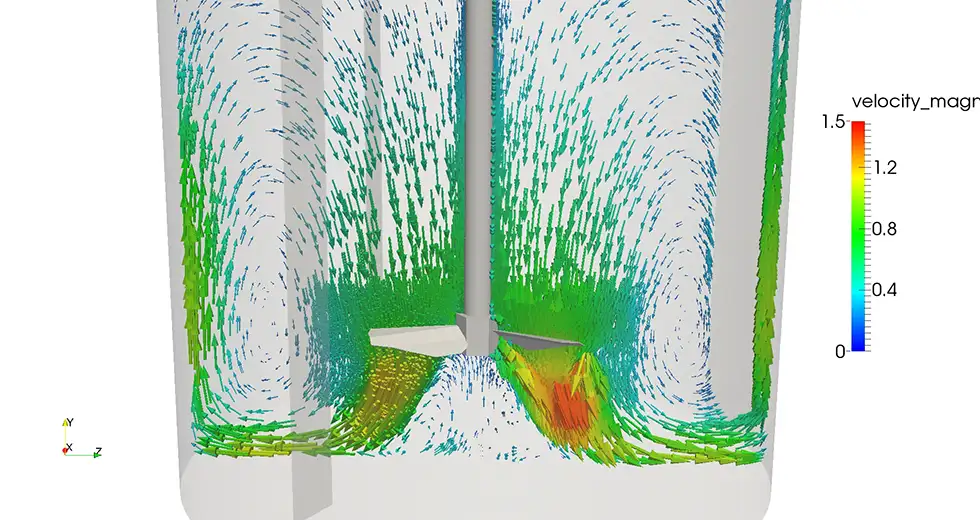

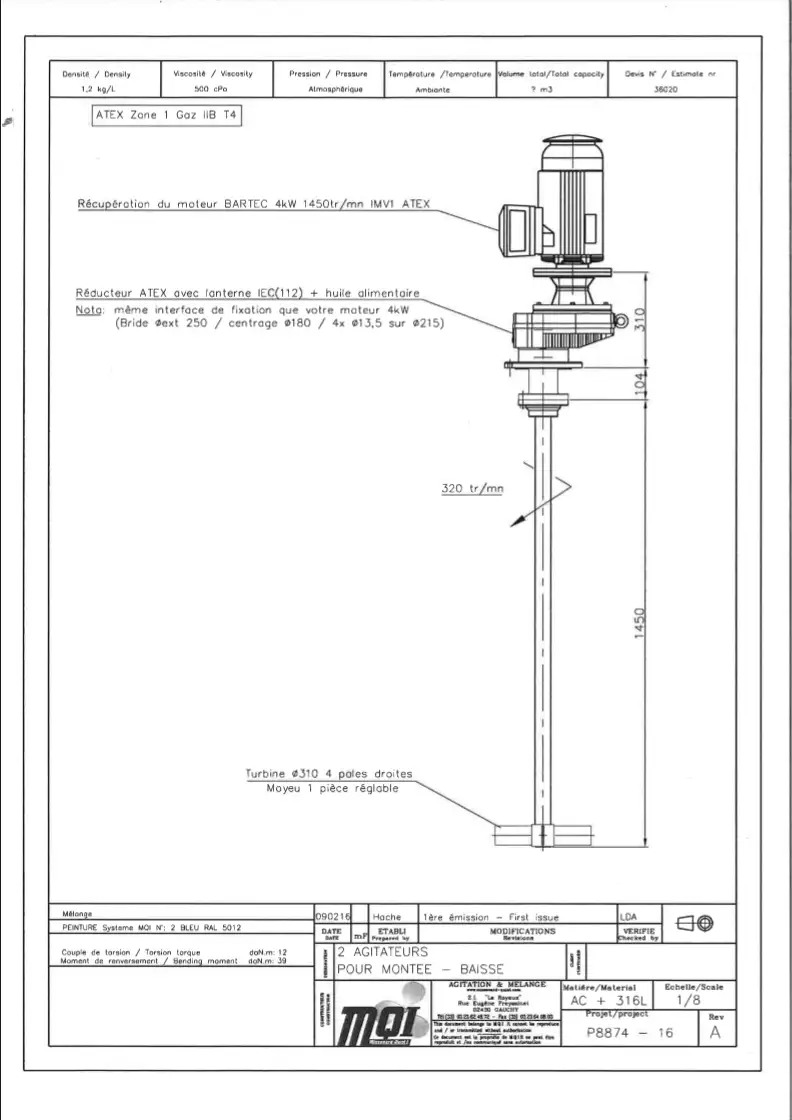

During the design phase, our engineering office can call on the following expertise: hydraulic calculation, extrapolation calculation, CFD, mechanical calculation, thermal calculation, fatigue calculation, sizing of mixing columns and sizing of fermentation mixers. We can make use of an extensive library of previous projects and if necessary, request tests.

Test laboratory

When choosing a new mixer, several criteria need to be considered: the nature of the products and their physical characteristics, the capacity and shape of the tanks and the mixing objective. The engineer in charge of the installation study selects the most suitable solution from the many types of machines available. Often, his choice needs to be confirmed by laboratory and semi-industrial tests, prior to final extrapolation.