Our know-how in industrial mixing equipment

Industrial mixing equipment: we design, build and install

A pioneer in industrial mixing equipment, Missenard Quint Industries conducts all of its business on a single site in France: engineering, manufacturing, test laboratory, shipping, administration. This organisation promotes synergy between our teams.

We also provide services to maintain your industrial mixer in perfect working order : parts, repairing, refurbishment, maintenance.

Design : defining and sizing custom mixers

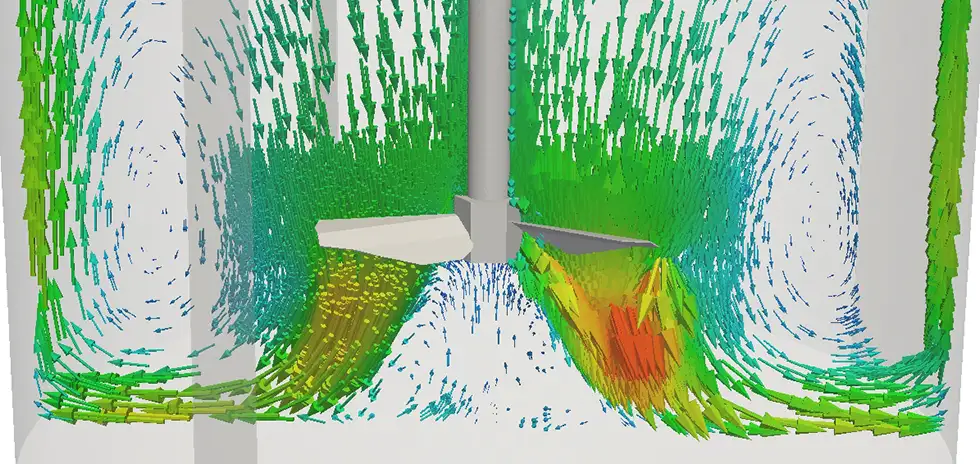

Missenard Quint Industries designs simple or complex mixers that meet the customer’s needs as closely as possible.

Our engineering office uses its expertise, the database of industrial agitation machines produced by us over more than 80 years and efficient calculation tools.

Manufacture : locally producedwith powerful industrial tools

We produce our machines locally, meaning we can control the manufacture and testing of parts in real time. This saves time for us and for our customers. To ensure the quality of our mixers, we prioritise European raw materials.

Our industrial plant, equipped with the latest technical resources, is divided into four sectors covering all stages of manufacture: mechanical, mechanical welding, assembly and testing.

Installation, commissioning, training : supporting our customers

Our fitters are certified for level 2 chemical risks (N2) and can assist customers during installation. They can either carry out the complete assembly, or supervise assembly by a team provided by the customer. We can assist customers with commissioning and validation tests and we can provide training for operators.

Missenard Quint Industries provides services designed to protect your mixer and maintain it in good working order: parts, repairs, maintenance and refurbishment.

Our range includes:

- top-entry mixers, side-entry mixers, bottom-entry mixers, in-process mixers

- mixing columns

- stand mixers, reactor mixers, submersible mixers, skid-mounted mixers, etc.